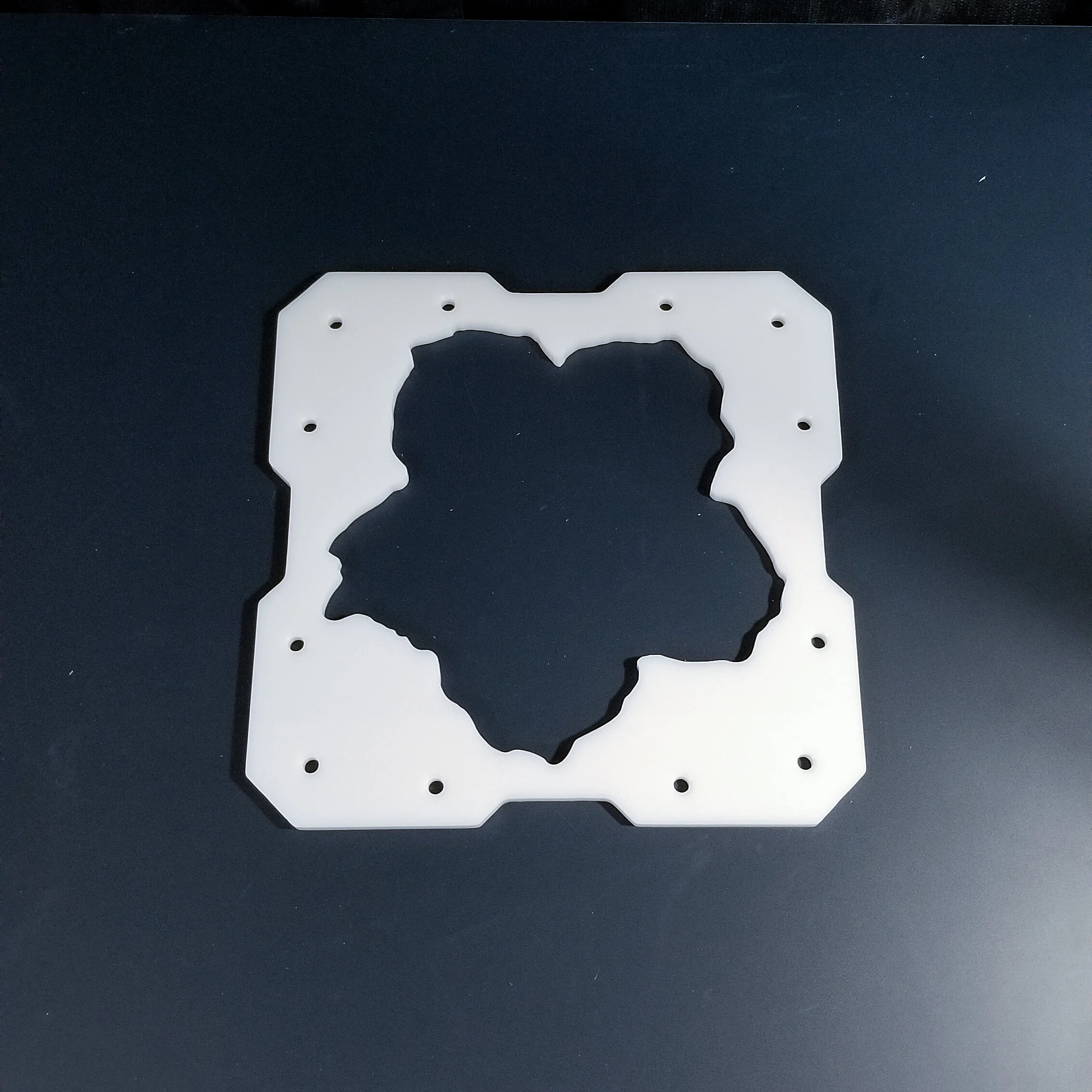

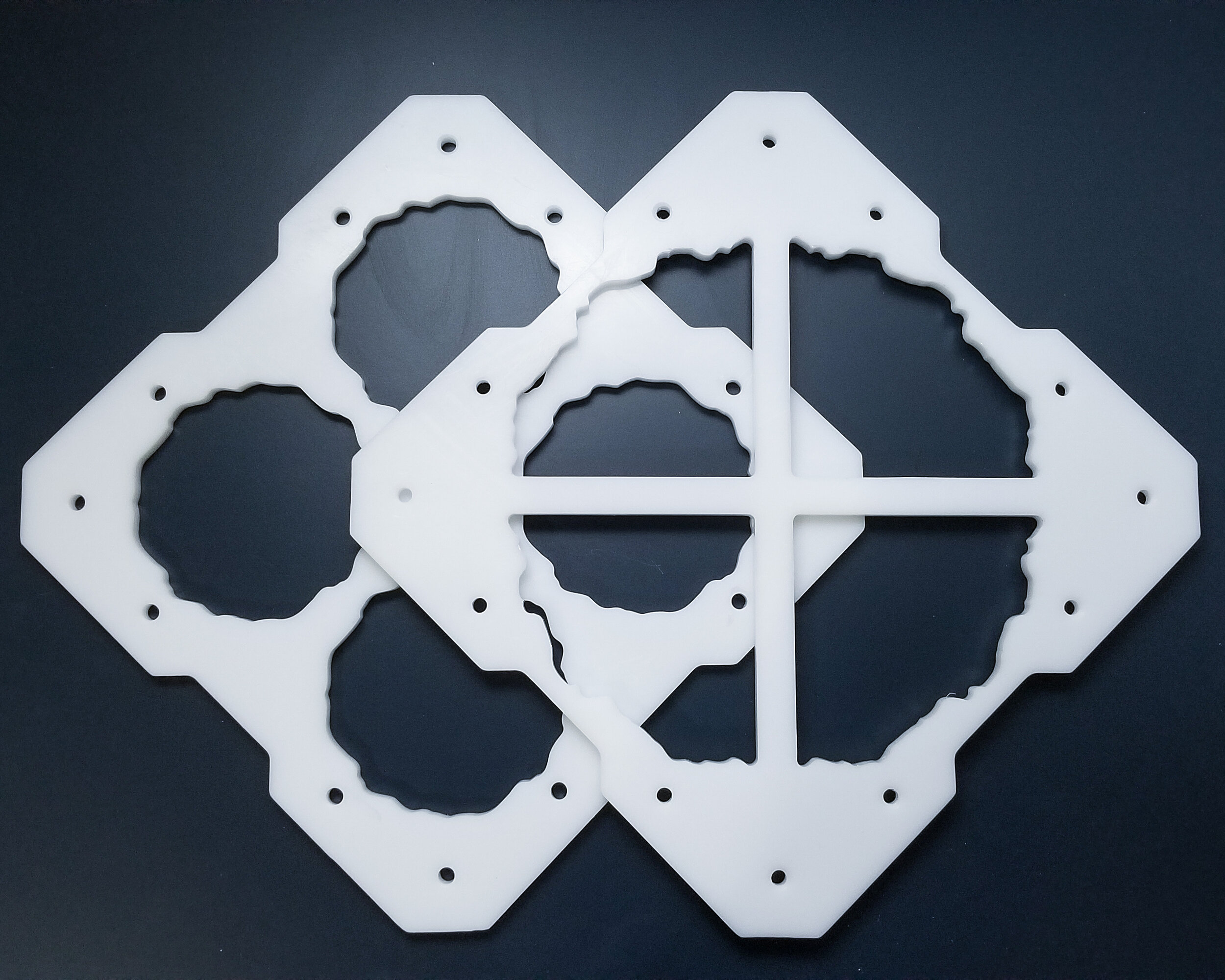

12x12 Set - Floral Shapes

12x12 Set - Floral Shapes

NOTE: Current lead time on top plates is 2-4 weeks.

Floral inspired shapes.

Our 12x12 Modular Sets offer you nearly limitless design options, customization, and modularity. Designed for the users that have a high cast turnover, those looking to work with many different designs and those wanting something with high durability that won't wear out.

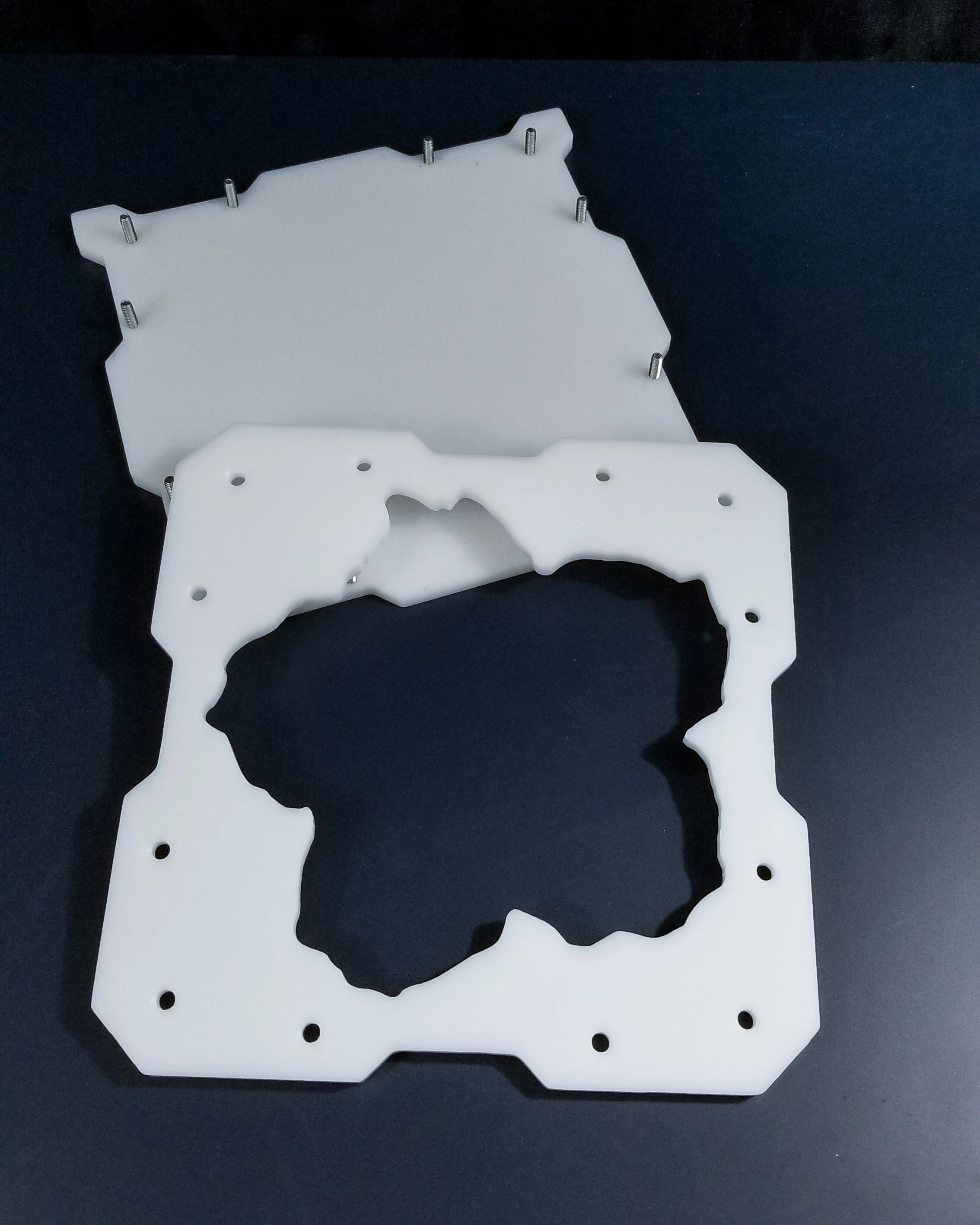

Each Modular Set comes with a 1 base plate and 1 top plate. You can have multiple of each but the key takeaway is that each top plate is interchangeable with the same size base plate. You can easily swap between different designs between casts or deploy multiple bases and increase your capacity.

These molds are highly durable and highly chemical resistant so they don't break down with harsh resins like silicone.

Modular molds do require a degree of experience with resin if you intend to use the bottom face as the finish face for your work. They are not the high gloss finish like our silicone molds are, they have a satin / semi gloss finish and the surface of the base plates may have small imperfections(although I do pick the best stock I can for the bottom plates). What does this mean? If you use the bottom face of the mold as the finish face then you will have to do a final finish coat to get the high gloss look. However, if you are using the open face of the mold as your finished side then it’s entirely up to you. :)

Demolding a modular mold is much different than the standard silicone mold. These molds are rigid and demolding can take some getting used to at first. I have a video linked below showing a few tips and tricks for demolding but to summarize here is a short list of a few things to keep in mind.

-Let your resin fully cure, do not demold early. If you can leave an impression with a toothpick in the resin then it is too early and the cast will still be stuck to the base plate.

-Rotate the mold as you pry the corners so you separate the plates evenly.

-Once separated you may slightly bend the plate to release the edges of the resin pieces from the mold. You can not peel the pieces out, they must be removed perpendicular to the plate for the most part.

-You may heat the plate with a heat gun to make removing the pieces easier.

Sizing:

Top Plate Thickness: .375” ~9mm

Multi Cavity Plates: 4.25”-4.5”

Single Cavity Plates: ~10”

Modular Molds:

A single or multi cavity mold system designed with modularity in mind. Once you have a base plate, any top plate of the same size series is interchangeable which provides you a lower cost solution for quick design changes and customization.

Highly Chemical Resistant Rigid Plastic.

Easy To Demold

Highly Modular And Customizable

Easily Scalable

Semi Gloss Surface Finish

Demolding Tips and Tricks: https://youtu.be/IX2eT8R4NAg